It’s hard to imagine a world without vanilla. Used for flavouring and medicinal purposes in the ancient past and in everything from ice cream to perfumes today. It has commanded our attention since its first use around 3500 years ago. Now, a new green chemistry technique uses enzymatic technology to give us bio-vanillin, proving that vanilla’s ‘plain’ reputation is undeserved.

A brief history of vanilla

The story of Vanilla begins with a humble orchid named Vanilla planifolia originating in Mexico, Costa Rica, and Honduras. The inhabitants of those lands (Mayans and Aztecs) used it in much the same way we do, to improve the flavour of their cocoa drinks. Today, vanilla beans are cultivated all over the world, including Madagascar (1946 tons), Indonesia (2600 tons), and China (1300 tons). It is the most commonly used flavouring in industry with ~60% used in food and beverage industries, and ~33% in cosmetics. The final 7% is used in pharmaceutical industries as a source of L–dopa (precursor to dopamine), norepinephrine, and epinephrine.

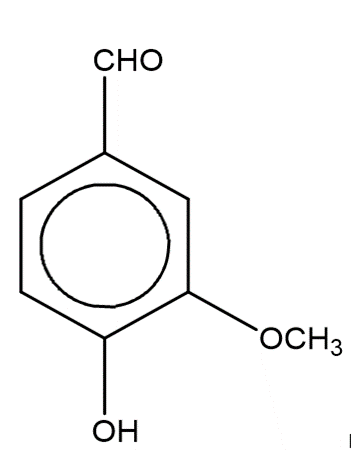

Vanilla is made of over 200 components but the most characteristic is vanillin or in chemistry-speak: 4-hydroxy-3-methoxybenzaldehyde. It simply wouldn’t be the same vanilla we know and love without this compound, so scientists have come up with a number of ways to get a hold of it.

Vanillin

The problem with natural vanilla

The demand for vanilla is insatiable. Globally, demand exceeded ~18,600 tons in 2016 and this is expected to grow another 6.2% by 2025. The problem is you need around 40,000 pollinated vanilla planifolia for 500 kilos of pods which produce a meagre 1kg of vanillin. Needless to say, it’s a lot of effort for such a tiny amount. Ultimately, Vanilla planifolia can only supply less than 1% of the sky-high demand. We need other ways of getting our hands on that eternally delicious vanilla flavour.

Is chemical/ synthetic vanillin sustainable?

Synthetic vanillin has taken over the vanilla market in recent years with over 90% of the American market being dominated by synthetic vanillin. Why? It’s about 100 times less expensive than the current beans so it’s an extremely economical option but has a number of drawbacks.

It leads to environmental pollution as it’s produced from fossil hydrocarbons like guaiacol. Another method involving lignin produces around 160kg of waste per 1kg of vanillin obtained so Canada and the US have shut down production of vanillin in this way. Furthermore, it’s not considered natural by EU and UK regulations. The use of chemical vanillin in the food and pharmaceutical industries is restricted because of this. The high purity of raw materials is an additional drawback, and it lacks substrate selectivity which can reduce process efficiency and increase the downstream processing cost.

Is there a better solution?

Biotechnology-based approaches can produce vanillin identical to the natural stuff. These approaches typically involve the bioconversion of natural substances like lignin, eugenol, and ferulic acid into vanillin. Microorganisms like fungi, bacteria, or genetically engineered microorganisms are used for this. The use of plant cells has also been investigated but does not yet appear to be advanced enough. Recently, the appeal of biotechnological processes has risen as consumers are increasingly demanding natural flavouring. They associate natural products with higher food quality and safety so see bio-vanillin as a superior option. Depending on the method, the cost is generally a lot lower than producing natural vanilla using old-fashioned biology.

Biotechnological vanillin

Enzymatic production

The enzyme-based approach involves the use of enzymes to release ferulic acid from raw materials. For example, SP 584 is an enzyme used to solubilised ferulic acid from Sugar beet pulp. The conversion of eugenol to ferulic acid and finally to vanillin using enzymes is another very efficient process. Enzyme manufacturing is a costly process, but new methods have been developed to increase the economic feasibility

Bacteria

This approach uses bacterial strains to utilise ferulic acid and isoeugenol for vanillin synthesis. Actinomycetes are good producers of vanillin from ferulic acid and lactic acid bacteria has also been used. S. sannanensis is another candidate for the production of vanillin from wheat bran. This is done by transforming ferulic acid esters into ferulic acid and into vanillin in a single vessel.

Fungi

Transforming agro-waste in vanillin using fungi has also gained popularity. Both fission yeast and baker’s yeast have been used to transform glucose into vanillin. Furthermore, P. cinnabarinus has been found to convert ferulic acid to vanillin quite effectively. Vanillin production from the enzymatic biotransformation of raw material by white-rot basidiomycetes has been reported.

Genetically engineered microorganisms

Genetic modification (GM) involves directly manipulating an organism’s genome using biotechnology. Even though GM is a highly controversial topic, there are a lot of benefits associated with its use. Using GM organisms to produce vanillin has gained attention due to its high production rate, which can increase its sustainability. For example, E. coli JM109 is a genetically engineered strain that can yield vanillin.

Transformed plant cells

This approach uses plant tissues to synthesise vanillin via the biosynthetic pathway as secondary metabolites. Hot chili peppers have been genetically transformed to produce vanillin from ferulic acid and modified hairy root lines of Beta vulgaris are effective in producing vanillin from ferulic acid. Low vanillin yield is a major limitation so the method would need to be developed further to be economically viable.

Problems

Whilst biotechnological vanillin holds a great deal of promise there are a few challenges that must be overcome. There are two major issues:

- Cellular toxicity which restricts microbial cell growth.

- The formation of unwanted by-products may get in the way of strain efficiency and the establishment of an optimized process.

Optimising bio-vanillin production

There are a number of ways that bio-vanillin production is being optimised. This includes using agro-industrial residues or wastes (wheat and maize bran) as the starting material to recycle waste. If more suitable microorganisms are discovered the yield could be improved. Improvements to the reactor designs and reliable online monitoring systems could be implemented for improved performance such as higher yield and lower cost. Recently, the addition of FeCl2 to the cultivation medium was reported to increase vanillin yield.

Conclusion

Nature-identical vanillin is always in high demand, especially as natural products gain increasing attention in developed countries. Future developments could lead to more reasonable pricing while providing closer flavour to natural vanillin. Ultimately, producing 100% of the market’s demand for vanillin by simply growing Vanilla planifolia is impossible and not sustainable. Using biotechnology to produce vanillin is not definitely green but using safe substrates, food-grade organisms and environmentally benign processing techniques goes a long way to being a more sustainable alternative to chemical synthesis.