Find a safe, biobased, low-odour solvent that works well with eScent’s formulation components and exceeds customer expectations

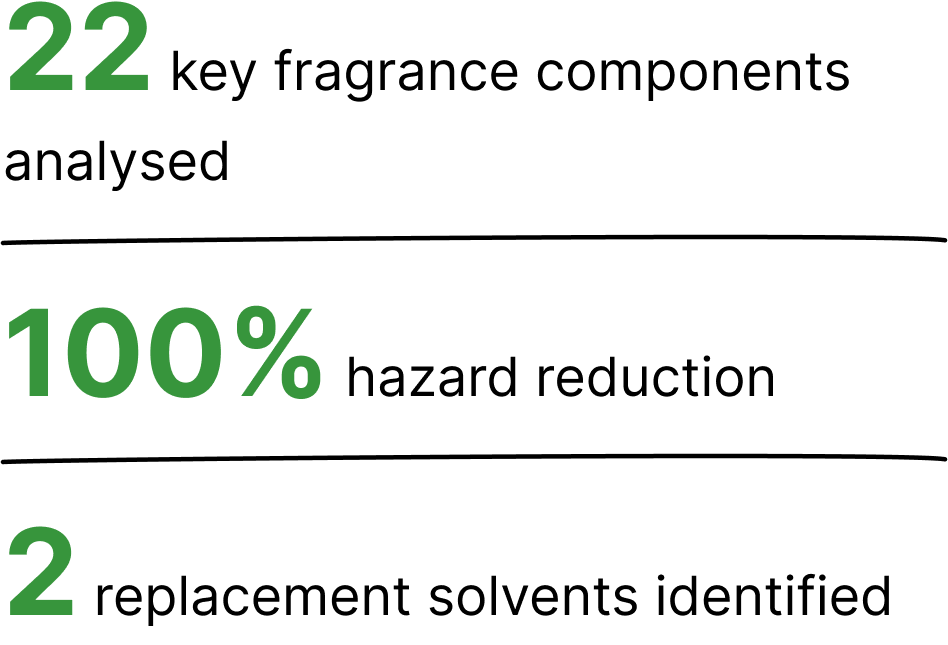

Two compatible green solvent candidates identified. 22 key fragrance components identified; their chemical structures and solubility properties analysed to optimise compatibility.

The rising trends of wellness, connected technology, and data-driven innovation led eScent founder Dr. Jenny Tillotson to design a platform technology that outperforms and replaces the classic perfume bottle. eScent’s patented wearable scent technology offers a profound, customised scent experience to each wearer, and has been funded by Innovate UK’s Sustainable Innovation Fund. Sustainability is at the core of the product design, and eScent set ambitious goals for safe, green materials in every component.

While the mechanical aspects of product development were well-covered by eScent’s engineering team, Jenny ran into multiple roadblocks when searching for a green alternative to the ethanol used in traditional fragrance products. She wanted to choose the best sustainable option, but didn’t have time to wade through the complex chemical terminology, wildly varying definitions of “sustainable”, and labyrinth of green metrics and certifications to find a solution that would work in her product. After conversations with the solvents industry and academic leaders in the field, Jenny came to Green Rose Chemistry to find an answer that would work for eScent.

Note: eScent is the trading name for Sensory Design & Technology Ltd.

We discussed the eScent product design philosophy, planned formulation components, performance requirements, and the safety and sustainability criteria that were most important to consider. We also considered eScent’s budget and the product development timeline, planning the Green Rose work to fit in with the myriad moving parts of the project. Our computational solvent selection process enabled us to eliminate labwork from the project, minimising costs and accelerating delivery. For results delivery, we skipped the traditional lengthy scientific report and instead produced a short, easily skimmable summary that communicated the important points while being quick to read.

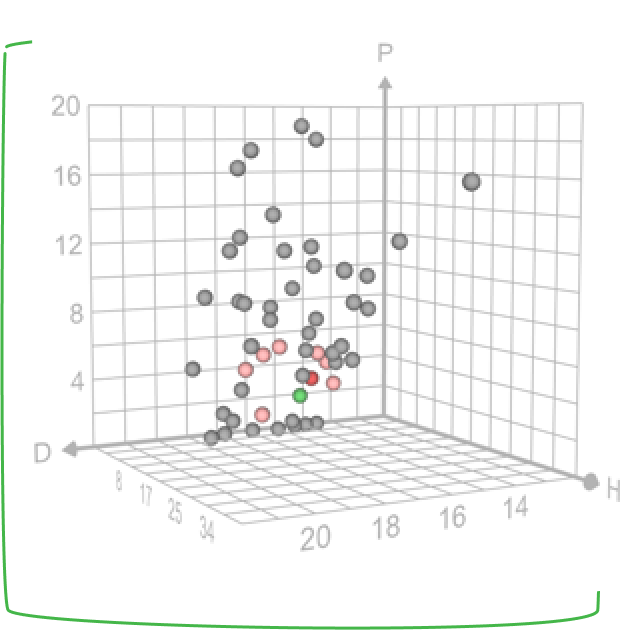

After agreeing the scope of the project, Green Rose began the deep work of delving into the chemical literature. We investigated the chemical composition of eScent’s planned formulations, analysing six fragrant essential oils and six health-promoting natural ingredients. Natural ingredients present a real analytical challenge, as the plant cultivar, growing region, storage conditions, and even weather during a specific growing season can change the chemical composition of the product. We used our expertise to focus the analysis on the most potent aroma chemicals, building a computational model that mapped these components in a 3D “solubility space”. Then, we applied the model to our safe solvent database, seeking solvents that would easily blend natural scents to create a beautiful sensory experience.

At the end of the project, we presented eScent with two safe, biobased solvent candidates that dissolved their formulation components and met other performance requirements. A tailored three-page summary detailed the physical properties of each solvent, including liquid range, vapour pressure, surface tension, viscosity, and water solubility, and compared each property to ethanol as a benchmark. Odour, cost, regulatory status, and biodegradability of the solvents were also vital considerations. Two UK suppliers were identified for each solvent, with pricing information.

In choosing low-hazard solvents, Green Rose didn’t stop at basic hazard labels, but reviewed additional available data and data gaps, evaluating whether new hazards were likely to be identified with more testing. With this approach, the recommended solvents are “future-proofed” against new regulations, ensuring they can be used for years to come.

At the end of the project, Jenny had two choices of biobased solvent that she could confidently say represented the best of the market, meeting eScent’s ambitious goal of a sustainable, ethanol-free fragrance formulation. Green Rose also contributed essential knowledge to eScent’s development process, establishing formulation-critical solvent characteristics and advising on the chemical composition of natural health-boosting ingredients.

By hiring Green Rose, Jenny accelerated and de-risked eScent product development, procuring unique green chemistry expertise without bureaucracy, exorbitant costs, or a lengthy hiring process. As a bonus, eScent hired Green Rose again to explore sustainable packaging options – but that’s a case study for another day.

“Green Rose Chemistry identified safe, effective green solvents for our renewable fragrance products. They were very coherent and easy to work with! We now have an understanding of the bio-solvents market, data to help us move to the next stage of the development process, plus new knowledge on bio-plastic packaging options. Hope to work with Green Rose again soon!”